Holy crap, someone complained.

After well over a thousand knives a customer emailed me and told me he was unhappy with his knife.

Well, I can honestly say that in 2 years it was the first and for some reason unknown to me, I was kind of excited about it, I knew an opportunity was ahead of me.

There is only one way to handle a complaint. First of all, here is a fella good enough to trust me with his beloved knife, regardless of the cost of knife, it was important to him. (I never judge people by their knives). Also, he went out of his way to drop the knife off and paid ten bucks to get it sharpened.

First of all, I would assume that this nice person did his homework and this is how I ended up with his knife. He was expecting nothing less than perfection and I let him down.

Only way to handle this is to apologize and fix the problem, any other solution is unsatisfactory.

Here is how I handled my first complaint.

I called the man and asked him to come over with his knife, I gave him the opportunity to watch me sharpen it. (Also, I went out and bought 4 very ripe tomatoes, the ultimate test)

He came over, a very nice young fella, no hard feelings here, this is about correcting a problem. Sharpening a knife by hand isn't like putting a piece of bread in the toaster and getting a perfect piece of toast every time. Gees folks, give me a freakin break, remember this is my first complaint :)

He brought a cutting board, a tomato and a lemon.......COOL.

Keep in mind that I knew that I was going to get his knife sharper than he has ever seen, I wasn't worried, I was excited. I never get a chance to sharpen a knife in front of someone.

Anyway, for the purposes of perspective, his knife was sharper than 90% of the knives I see, which again was cool for me, it meant that this guy knew what a sharp knife was.

I re-sharpened the knife and within 5 minutes the knife was ready to go home with him, problem solved and he was happy, we hugged and high five'd, all good.

Now came the fun part, I asked him to let me experiment with the knife, using the tomato and the lemon as a guide and this is important folks, what I am about to tell you is the important.

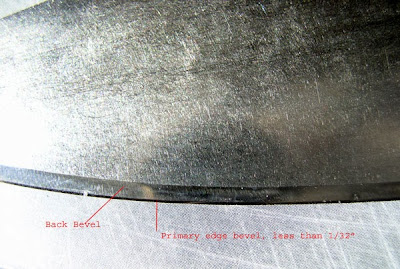

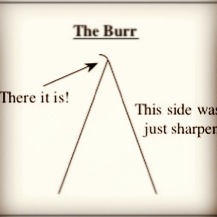

I sharpened the knife at 1, 000 grit (albeit on one of the best stones in world....sorry about that). The edge was beautiful, he was able to slice the tomato without using any pressure, so just the weight of the knife was enough to penetrate the skin. (SOUND EASY?.......go take your sharpest knife in the house and try it ).

We repeated this process up to 6,000 grit at which point he took the knife home, very happy. I gave him his money back ( he didn't want to take it but I forced him too, he was a nice fella)

Anyway, what I got from this was the opportunity to sharpen a knife and be able to have immediate feedback from a customer as he tested his knife on the skin of a tomato.

Bottom Line...Customer happy and a lesson learned for me.

So what was the problem in the first place you ask?

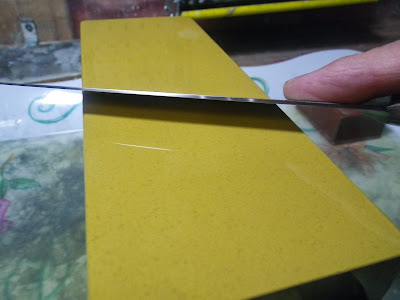

The knife's Bolster had to be reduced a little, it was preventing the edge of the knife from making full contact with the cutting board.

I may have sharpened it at too high a grit, so the edge would slide over the tomato and require a little force in order to break the skin.

In any event, it was not to the customers liking so I fixed it, it was actually pretty cool.