Hi folks, long time no see.

I was kind of running out of things to talk about and worried that anyone reading my Blog would find it getting stale.

I was asked to talk about steel and how it has impacted my approach to knife sharpening, and indeed if it has had any impact at all

Also do we need to have a knowledge of all the Alloys used to created the knives we love to sharpen

Culinary steel reminds me of bread or wheat to be specific. Like bread, steel has changed dramatically over the last 50 years, there are so many more different types of steel now, it’s hard to keep up back then it was basically carbon steel and when butchers used a steel hone to keep their tools sharp I believe it had more of a positive influence on edge retention because the steel was not so resistant to abrasives

Now we basically have carbon steel and stainless steel knives. Not that long ago, stainless steel knives were considered inferior to carbon knives. Still to this day, some of the best knives I work on are the old, 60 plus year carbon steel knives like Sabatier. Anyone who sharpens knives know that these knives not only take a superior, startling edge but they are easier to sharpen than the mass produced, inexpensive stainless knives. I’m quite sure it’s due to the inferior quality of the steel making them resistant to abrasives due to the impurities

Now however, stainless steel has come a long way and several varieties are quite amazing and take outstanding edges. Some of the top Blacksmiths create culinary masterpieces out of steels like VG 10, R2, SG2 and the dreaded ZDP 189. Also what some consider the best best Japanese steel, HAP 40, a powdered steel, ridiculously hard (64-68) and composed of the usual premium alloys like Carbon, Chromium, Molybdenum, Vanadium, Cobalt and Tungsten.

As for the wonderful carbon steels we still love the Shirogami, Aogami (1 & 2) and Aogami Super.

We can just Google call of this or check out an awesome book by the Canadian Kevin Kent who produced The Knifenerd Guide to Japanese Knives . He and Naoto have forgotten more about steel than I’ll ever know

So how has this information, this plethora of amazing steels impacted the way I sharpen and knowing what I know now about steel, which is still limited, has it made me a better sharpener?

To be honest, we don’t need to know about all these steels and the percentages of each alloy in every steel to be able to sharpen well, in fact it really has not made much of a difference to my edges from a practical point of view. If I was a guitar player, obsessed with it, would knowing what type of wood was used, what the strings are made of make me a better guitar player.? No, however that knowledge would be helpful in picking out the best guitar . So knowing what these dream knives are made of will guide us towards the right knife fir us perhaps

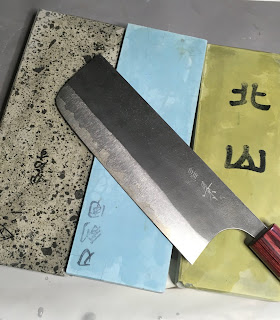

The only thing that influences my sharpening approach is know if the knife is hard or soft. When I pick up a hand made carbon or stainless knife ( made of the good stuff) I’ll adjust my sharpening angle accordingly, it will be more acute, around 12 deg per side and I’ll finish the knife at 5,000 grit in most cases. The quality of the steel allows me, drives me to do this to get the most out of the knife for the customer.

Also, for the extremely hard steels like HAP 40 and ZDP 189 I’ll always grab a Shapton Glass coarse stone to form the Initial Burr

You don’t need an in depth knowledge of steel to get all of the joy that freehand sharpening has to offer. It’s just another stage of the journey that enhances the overall process .

Thank you for sticking around

Peter Nowlan

( Oh, I’m on Tik Tok now doing sharpening videos as “ @SharpenerPeter)

.