I can't believe that it has been a decade since I opened up my business. If there is anything that I have learned it's that I don't know everything. After 10 years and thousands of knives, each bringing with it a new experience, I'm continuously surprised how much there is to learn about knife sharpening.

The thing is, you can still sharpen knives and do that very well without trying to learn new things but often, and I have seen this occur, it's simply Ego that prevents people from picking up new ideas because they are now willing to listen, they are unable to accept the fact that someone else may know more, or just know something different than they do. These folks just carry on using the same process from day one, which again, can work just fine. However, if I was like that, I would not be half the sharpener than I am today and I also know that over the next ten years, I will continue to learn. I have no ego so it allows me to be a sponge and absorb new material and filter some of the stuff out.

I just came back from two weeks in France, I didn't learn anything new about sharpening but I did learn a heck of a lot about wine.

Asymmetrical Edges

Several years ago, the mere thought of having to sharpen a knife that did not have a 50/50 grind terrified me, well not really but I had no real idea how to deal with it. Since that time I can tall that many sharpeners don't because the knives that started off with asymmetrical grinds just became somewhat symmetrical because the person sharpening did the same thing on both sides, made no adjustments to maintain the edge geometry either because he/she preferred a 50/50 grind or they didn't know what to do. That was me back then about six years ago and it has only been in the last few years that I have reached a spot that I'm completely comfortable with the process.

This is how I managed to overcome the learning barrier:

First off, I really had no idea what a 70/30 grind meant, what the numbers mean for example and how do I relate those numbers to my sharpening. Was it 70% on one side and 30% on the other in terms of angle, time spent, number of strokes, pressure?

After doing research on the forums, I ended up doing this 7 strokes on one side and 3 on the other which kind of worked but just didn't seem right. Finally I called my friend Jon Broida because I knew that he spent time in Japan and besides, he is a brilliant sharpener and always eager to share information.

|

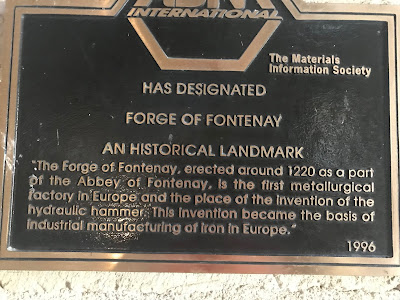

| 13th century forge at the Abby of Fontenay in Burgundy |

Anyway, Jon revealed to me that the creators of the knives, like the Misono with its 70/30 edge do not really get concerned about the numbers, they don't measure things, there is no ratio, they just make sure that one bevel has a larger surface area than the other. I think these ratios like 70/30, 80/20 are numbers that we have applied to knives, the Japanese don't.

So with that in mind, I stopped stressing about the meaning of the "ratios" and just started making sure that the surface area on the right side of the knife is larger than the left side. Since that moment, the sharpening process became very easy for me and it still is today.

(This is a huge hammer used in the forge that was built by monks, it is powered by a massive water wheel that is not show but it's behind the hammer. 1220)

This is how I sharpen a Misono for example.

First of all I know that I have to adjust something to retain the wide bevel on the right side, the 70 side so do that, to make that bevel wider than the other side I just have to do three simple things. have to reduce the angle so that it matches the right side. The sharpie will help here but it only makes sense that If I sharpened both sides at 15 deg for example, then eventually both sides would be the same, it would be a 50/50 grind.

I start on right side on my coarse stone and raise a burr using whatever pressure is required to accomplish that, just like any other knife.

I flip the knife over and now is the time to make an adjustment. I raise the angle slightly, I use a little less pressure and I spend less time on the left side, (the 30 side) because the surface area of this bevel is not the same size as the right side bevel, in order to maintain that difference I need to adjust the angle, pressure and time, I reduce them all but I do raise a burr on the other side.

If this sounds complicated, it just "sounds" complicated, it's easy. Just start by adjusting the angles on either side, that will do the most important job. Forget about counting strokes, i.e. 7 on one side and 3 on the other. Use the amount of strokes necessary to form burrs on either side of the knife but keep in mind the overall goal, to ensure that the surface area of the bevel on the right side is wider than that on the left and if it turns out to be a 70/30 difference in size that's great but it doesn't have to be difficult. You will be surprised just how easy it is by simply adjusting the angles on either side and it's just by 2 or 3 deg.

That's how I do it, I have restored many knives that were asymmetrical when made but became 50/50 over the years of sharpening. I do it by following the steps I described above, there are no tricks.

Grinding/sharpening wheel from the year 1220. The surface of this wheel is extremely flat and smooth. I told you, sharpening is in our blood..

Thanks for reading this, if you have any questions just fire them away a sharpenerpeter@gmail.com.

Respectfully

Peter Nowlan

Halifax, NS, Canada.